Highlights of GTUsers F6FA Conference 2023

The much-awaited Frame 6FA User Group Conference was finally organized in sunny Budapest, Hungary. Participants were treated with a workshop tour to General Electric manufacturing and repair center in Veresegyhaz. The conference was successful with record-breaking number of attendees engaging in lively discussions and forging new connections.

If you missed out on this unforgettable experience, don't worry! You can find out about all the webinars, conferences, and upcoming meetings at GTUsers.com. So why not join us for the next one and be a part of the user group?

Users Session

|

The first Session was dedicated to end users only. The end user day featured a number of fascinating case studies covering noteworthy events and lessons learned. As if that wasn't enough, attendees also got to participate in an engaging Q&A session with fellow users. This session covered the burning questions that had been gathered via the pre-conference questionnaire and sparked some lively discussions. All in all, it was an exciting and informative experience for everyone involved! Some of the key lessons discussed:

Are you an owner or operator of a F6FA gas turbine? If you're not already a part of the GTUsers Users Group, it's time to join. Head over to GTUsers.com and register now to get all the latest news, insights, and discussions surrounding this unit. Join the community and take your F6FA expertise to the next level!

|

|

General Electric

|

OEM GE Gas Power Session Conference GE day included the following main topic areas:

And, last but not least, the Q&A session was a crucial part of the event, where end-users had the opportunity to ask detailed questions. GTUsers and the SteerCo collected questions from end-users in advance, ensuring that all queries were answered thoroughly by GE experts, leading to lively discussions and a deeper understanding of the topics presented.

|

|

3rd Party Service Providers

|

MJBI was pleased to participate in this year’s F6FA Users Conference in Budapest on 18th April 2023 and would like to thank all those who attended the event. MJBI is a highly experienced independent gas turbine service provider dedicated to providing our customers with a wide range of technical services and innovative solutions that add value to their operations. Eric Osterberg (Business Development Manager) used the opportunity to highlight the wide range of aftermarket maintenance, repair and overhaul solutions MJBI continues to develop for the advanced technology 6FA gas turbine fleet. MJBI works closely with end users under LTSA or on a transactional basis and fully understands what it takes to successfully operate and maintain their critical rotating equipment packages. Using recent examples of 6FA maintenance, repair, overhaul and supply scopes that MJBI has performed, Eric was able to demonstrate to the Users Group MJB’s significant 6FA product and service offering. More information about MJBI products, services and capabilities can be found at mjbi.com

|

|

|

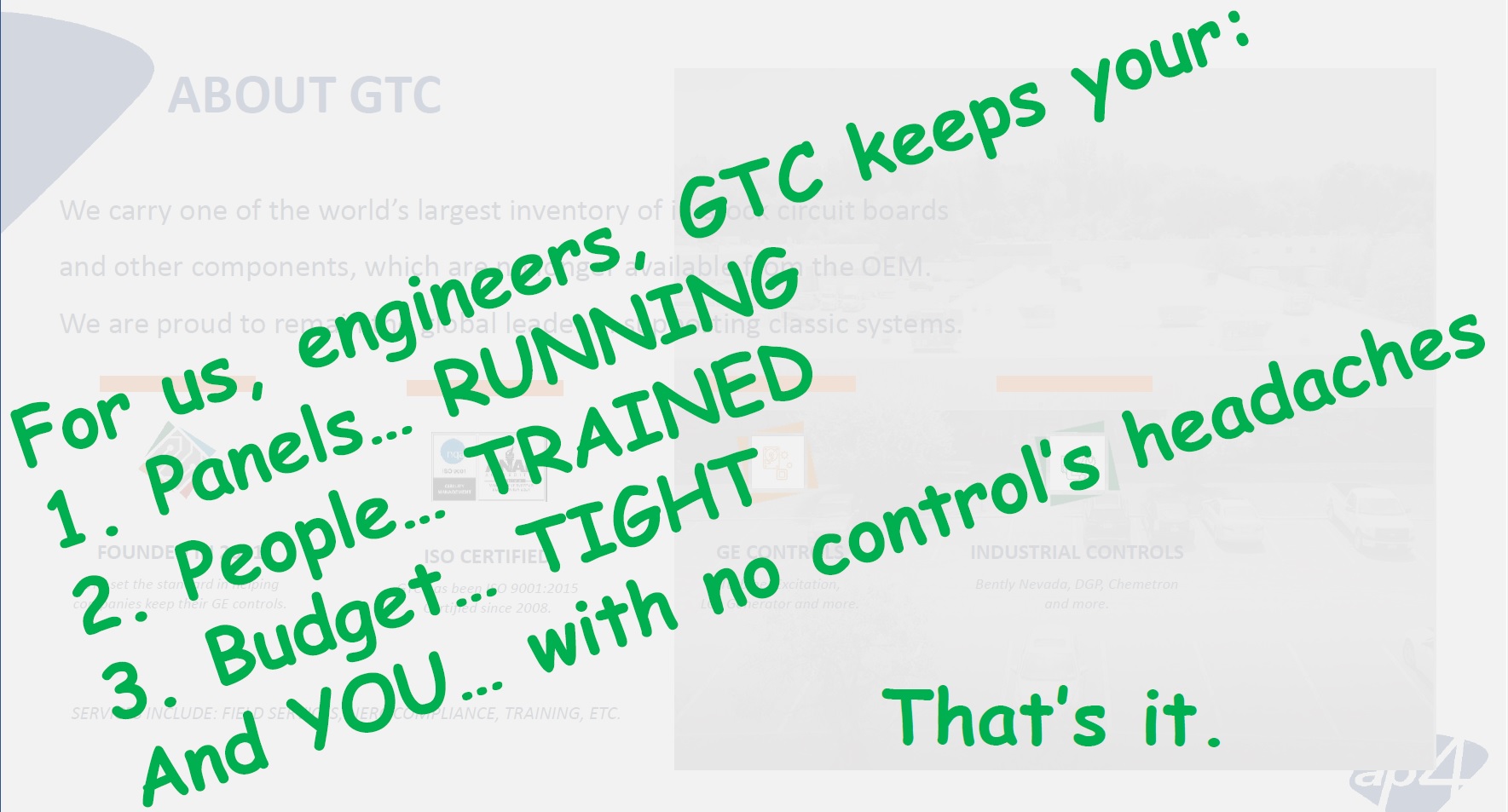

MECHANICAL DYNAMICS & ANALYSIS MD&A's presentation covered the repair and new manufacturing of DLN2.0 and DLN2.6 fuel nozzle assemblies with end covers. Understanding the crucial role of the fuel nozzles is important to avoid operational problems like:

MD&A showcased several case studies where a combination of thorough fuel nozzle refurbishment and MDA's specific upgrades resulted in significantly improved combustion reliability, low emissions, and extended component lifetimes. These upgrades were also shown to significantly reduce owning and operating costs by delivering "same-as-new" quality at a fraction of the cost of purchasing a new part. Just to mention some of the refurbishment tasks:

MD&A also showed their capabilities to repair AGP components and thereby extend the life of critical assets. |

|

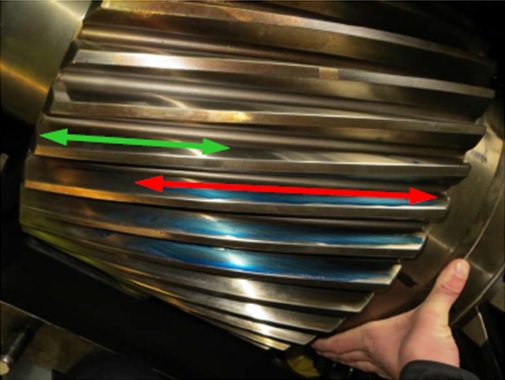

GTC Control Solutions a Division of AP4 Group always have interactive case studies presented and this time a topic "Being an Owner’s Engineer during controls upgrade project" was discussed.

GTC has been involved as an owner's engineer in a number of control system upgrades, including MarkV to MarkVIe and EX2100 to EX2100e upgrades. In this role, GTC ensures that the scope of work is complete and that no important features are missed during the upgrade process. This helps to ensure that the upgrade is successful in improving the performance and reliability of the gas turbine control system.

|

|

|

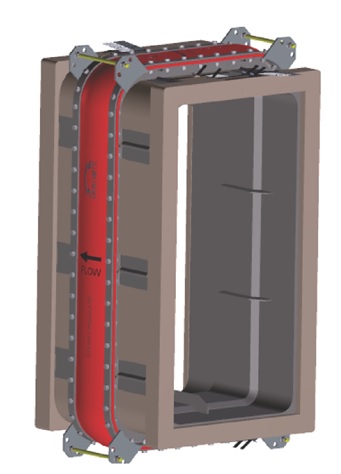

Dekomte is a leading manufacturer of fabric and metallic expansion joints and bellows, engineered to compensate for the changes in length caused by shifting temperatures in ductwork. Axial, lateral and angular movements are compensated for. Dekomte expansion joints are available in any geometric shape (round, square, oval, multi-sided) and in any size. Dekomte's approach to expansion joint selection and maintenance is based on being a solution provider for their customers. They explained the technologies, selection criteria, and importance of proper maintenance for expansion joints, including:

Dekomte presented a number of compelling case studies, including one involving the transition of a 6FA gas turbine. In this project, Dekomte supplied a complete new expansion joint between the GT and HRSG, complete with internal insulation. The installation process was carried out with impressive efficiency, resulting in minimal outage duration and maximum cost savings for the customer. |

|

|

At the 6FA user conference, there were also several other important third-party service providers present, including: |

|