Highlights of GTUsers AE94.2/SGT5-2000E Conference 2023

Get ready to relive the excitement of the first GTUsers user conference of 2023, held from February 27th to March 2nd! After a long wait due to Covid, the conference brought together a diverse group of participants including end-users, third parties, and OEMs from different companies and regions. With a wide range of topics, lively discussions, and valuable feedback from attendees, it's no surprise that we're already planning to organize this conference again in 2024!

To stay up-to-date on all the latest news about our webinars, conferences, and upcoming events, be sure to visit GTUsers.com.

Users Session

|

Day one of the conference was packed with excitement as end-users presented their short plant presentations, covering the most important events of the past three years. After such a long break since the last user meeting, it was a much-needed opportunity for participants to share and discuss their experiences. Throughout the day, there were many key topics discussed, including the compressor vane carrier life limiting factors and plant solutions, plant peaking performance and flexibility, and operation experiences using Light Fuel Oil in DLN mode. Attendees also got to hear about exhaust diffuser cracking and new design experiences, as well as DCS plant control upgrade experiences, with tips for those planning their own control system upgrades. Other notable topics included eHGPI experiences and inspection findings after 46,000 EOH, the modification of a CCPP into a synchronous condenser, rotor LTE and the rotor swap process, generator rotor coil failure and the corrective actions taken and Si3D+bearing upgrade. The day wrapped up with end user Q&A and discussions. |

|

Ansaldo Energia

|

Ansaldo Energia met the end users of AE94.2 and SGT5-2000E gas turbine in Rome. Many topics have been submitted from the Users and the Steering Committee before and during the meeting, giving Ansaldo Energia the opportunity to reply in detail and to set up an effective session, placing the expertise at the core of its products and solutions. Ansaldo day included the following main topic areas:

AE summarizing comments:

|

|

Siemens Energy

|

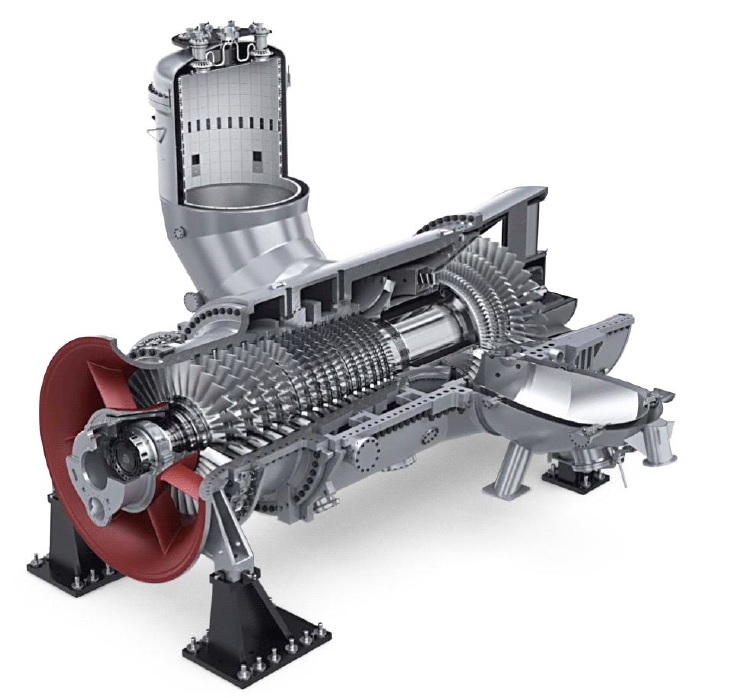

On February 28 and March 1, #teampurple had the honor to be invited by #GTUsers to the V94.2 User Conference in Rome. What a difference to meet our customers in person after a two-year restriction to net meetings, due to the pandemic. We experienced great discussions during the marketplace showing us the deep interest of our customers in a broad field of topics. This has been shown on the basis of several presentations, e.g.:

Additionally, presentations were given about the new turbine blading Si3D+™ upgrade, lifecycle topics (e.g. extensions of intervals and end of lifetime), digitalization, and flexible operation. The high reliability and robustness of this type of gas turbine can be very well demonstrated by the fact that the customer of the first V94.2 still operates it (for 42 years) and participated in the conference.

|

|

3rd Party Service Providers

|

Planning a control upgrade – A case Study by Emerson, Laurence O'Toole / Emerson

Emerson presented what project steps are needed to make a successful control system upgrade:

An Emerson upgraded GT control system case study was reviewed where latest criteria set to control systems in cyber security, connections to enterprise systems, remote monitoring, and increase in SIL rating were implemented.

|

|

|

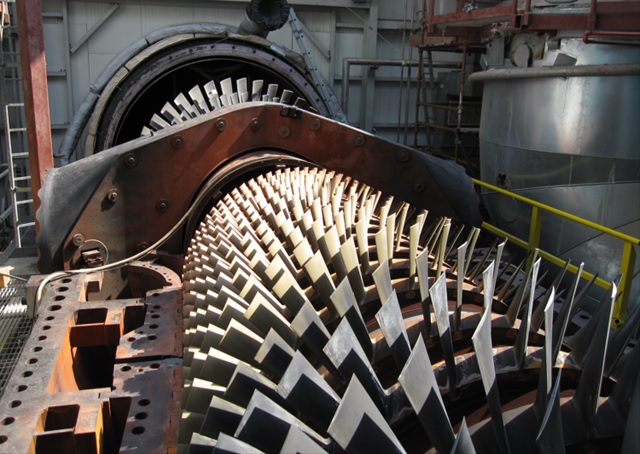

Sulzer upgrade of a V94.2 to version 7, Ervin Mom/ Sulzer Sulzer Upgrade Case Study covered a project of a V94.2 to Version 7. What is most valuable feature to the Client: Initial step in an upgrade project is to define what is the most important feature for the Operator:

Technical evaluation of the selected scope. TBO extension covers possible life extension scope including damage mechanics analysis, condition of turbine components exposed to during operation and component material and coating features. Sulzer can upgrade components from any version to the required version regarding TBO life and power & efficiency increase during a repair cycle or supply components with required design and base material. Upgrade Strategy is established with the Client: Aim to upgrade components during a regular outage and depending on the version of the components, their service life and the resulting component conditions, the:

For the combination of TBO extension and power & efficiency increase Sulzer supplies and replaces components which has required properties for the upgrade.

|

|

|

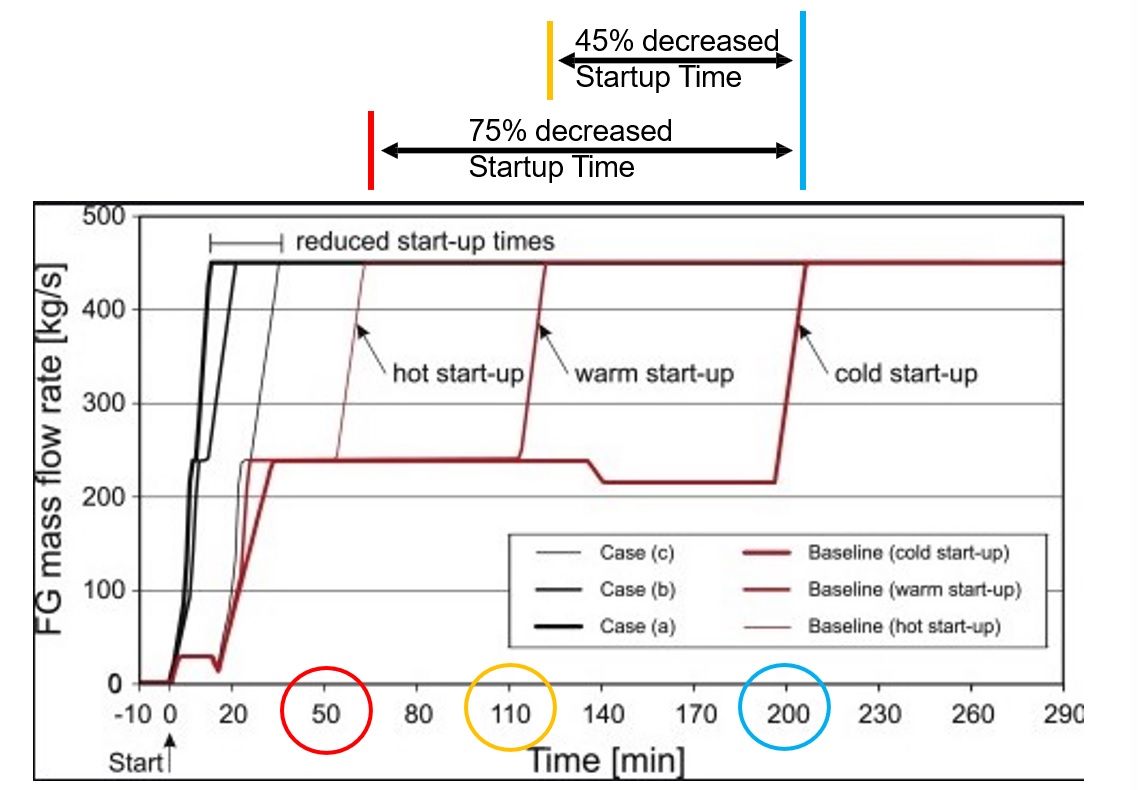

Advanced Steam Turbine Warming for high economic startup improvement, Werner Arnold / Arnold Group

Werner Arnold from Arnold Group made a presentation of their successful Advanced Single Layer Turbine Warming System including detailed axial flow steam turbine case study. Benefits:

Arnold full services for gas turbines include:

|

|

|

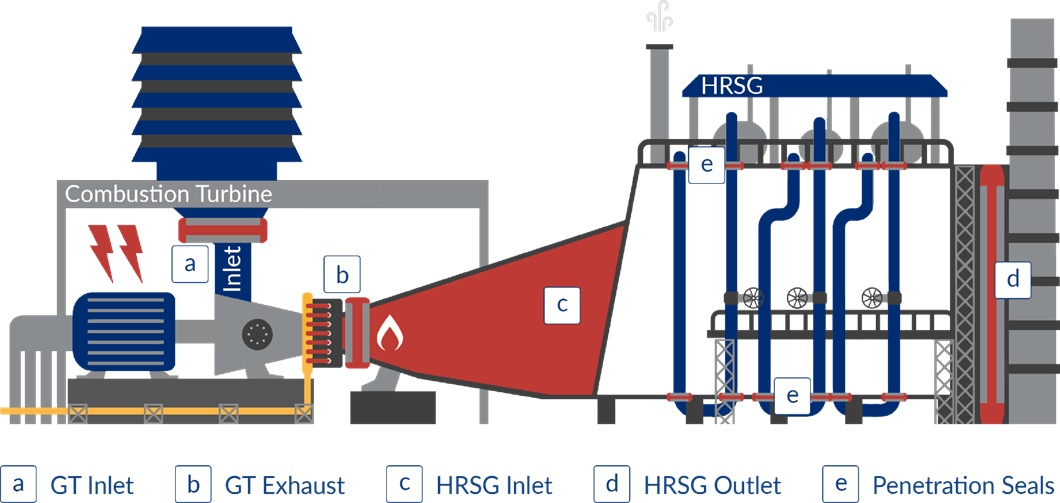

Advanced exhaust expansion joints, DeKomte

Dekomte manufactures fabric and metallic expansion joints and bellows, designed and constructed to compensate for changes in length due to shifting temperatures in duct work. Axial, lateral and angular movements are compensated for. DEKOMTE expansion joints are available in any geometric shape (round, square, oval, multi-sided) and in any size. Dekomte explained their solution provider approach to the technologies, selection and criteria for proper expansion joint selection and maintenance, in particular:

Dekomte also explained reasons for loss of insulation and effects of insulation loss. With DeKomte methods condition of insulation can be inspected at site and corrective solutions provided accordingly.

|

|