Highlights of GTUsers V94.3A Conference 2022

It finally happened, the long awaited V94.3A conference was held in Rome 10-13th October. After 3 years of webinars only, the face to face live event felt like it was much needed and participants from different companies enjoyed to finally meet in person once again. Wide range of topics, lively discussions and high number of participants representing 49 power plant companies and 12 Sponsors made this event successful for End users, 3rd parties, Siemens Energy and Ansaldo Energia.

V94.3A event will be organized again in October 2023.

More information of the held Webinars/Conferences and coming meetings can be found at GTUsers.com

Users Session

|

The first day was dedicated to end users. The end user day consisted of numerous case studies on noteworthy events and lessons learned. Users Q&A session was added in the end of the User day where questions listed as part of the pre-conference questionnaire was discussed in detail between end users. Some of the Key lessons discussed:

Many more topics were discussed including a lot of technical information and experience sharing between end users during the user Q&A session. If you own and operate a V94.3A gas turbine and are not part of GTUsers Users Group, please visit now GTUsers.com and register.

|

|

Ansaldo Energia

|

Ansaldo Energia day

AE summarizing comments: Starting from the awareness of the existing fleet, the market and the energy transition challenges and opportunities, Ansaldo Energia presented its vision of this gas turbine improvement, thanks to its 20+ years field and upgrading experience. These values, together with the continuous AE94.3A frame technology development make up a wide offering product portfolio, including digital and decarbonization solutions, that have been presented to the end users to support them in a sustainable and competitive energy transition.

And of course most importantly; AE answered with detailed replies to end user questions during the Q&A session. Again GTUsers with the SteerCo collected end user questions in advance and all questions were replied in detail by Ansaldo with lively discussion.

|

|

Siemens Energy

|

OEM Siemens Energy day Siemens Energy gave detailed lectures and presented products like Advanced Turbine Efficiency Package (ATEP) and Advanced Plant Efficiency Package (APEP), which help us all to further decarbonize, but also solutions for grid stability like the Rotating Grid Stabilizer, which is needed for the energy transition. Some of the other highlights from Siemens day were:

SE summarizing comments: And of course most importantly; SE gave detailed replies to end user questions during the Q&A session. Again GTUsers with the SteerCo collected end user questions in advance and all questions were replied by SE with lively discussion.

|

3rd Party Service Providers

|

MECHANICAL DYNAMICS & ANALYSIS MD&A, longtime supporters of GT Users were delighted to be able to present in person to the 2022 V94.3A User Group. MD&A’s San Antonio Service center is an industry leader in gas turbine component repair, our facility has leading-edge equipment and repair techniques with proven expertise on multiple-frame gas turbine hot gas path and combustion components. Our enhanced Siemens V94.3A Turbine new parts use proprietary advanced technology. The improved designs of the components, based on the extensive repair history of these OEM products, extend the service life by minimizing oxidation, creep, and metal temperatures. MD&A presentation – ‘Review of MD&A V94.3A4X New Make Components After their 1st Service Interval & Life Time Extension Case Studies’ covered;

|

|

|

|

Arnold Group, The most advanced Turbine Insulation combined with high performance heating System. Werner Arnold & Pierre Ansmann from Arnold Group made a presentation of their succesfull Advanced Single Layer Turbine Warming System including detailed axial flow steam turbine case study. Benefits:

Arnold full services for gas turbines include:

|

|

Bohemia Market presented Cybersecurity concerns of DCS and GT control Systems. What is cybersecurity and how safe is your control system? Equipment:

Personnel:

CVE - Common Vulnerabilities and Exposures program identify, define, and catalog publicly disclosed cybersecurity vulnerabilities. Bohemia Market has mapped and identified vulnerabilities in its Knowledge Base Spare Parts Database and assists Clients to Identify, Evaluate an Act convert ing Cyber-Security Requirements into Actionable Tasks:

|

|

|

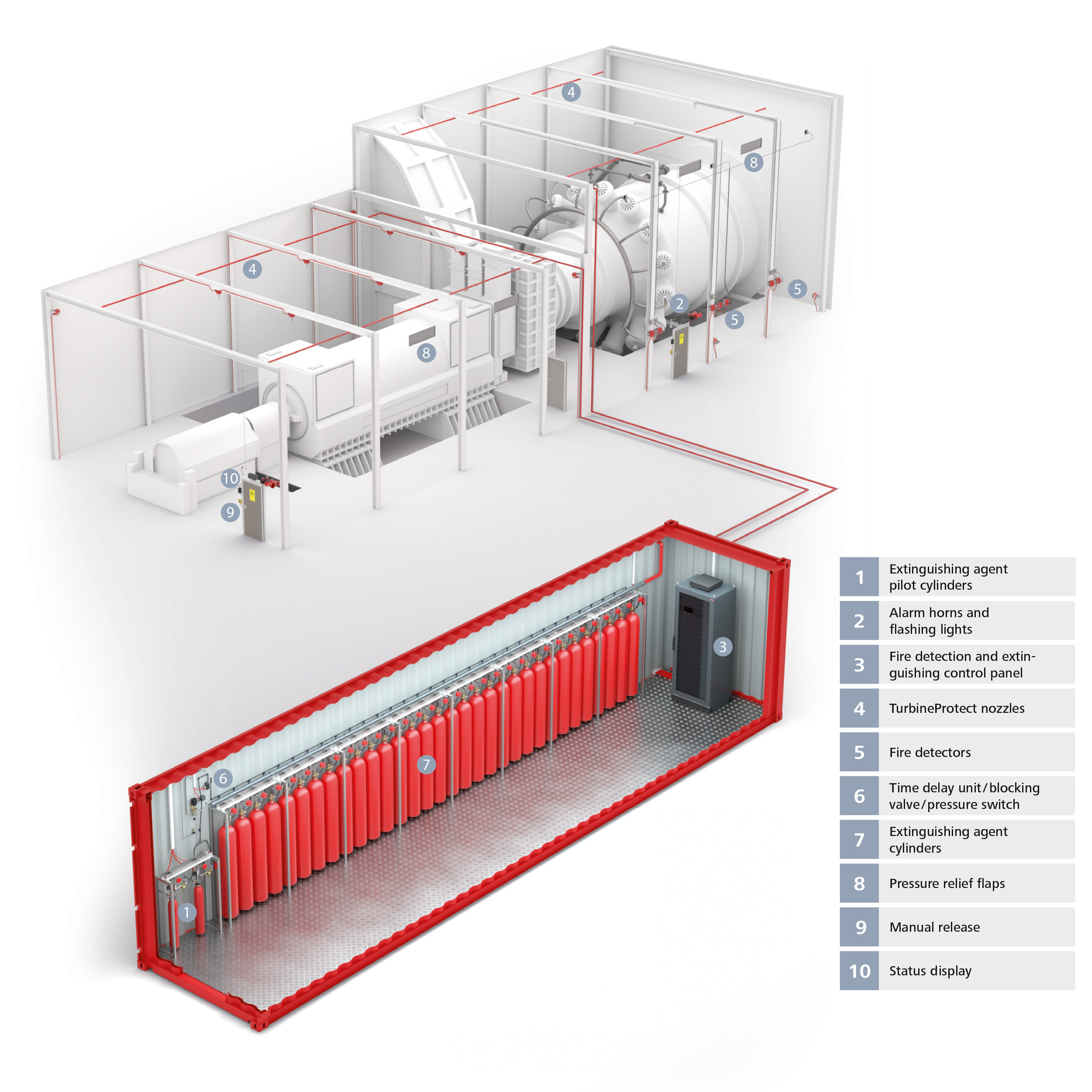

Identify and control fire risks on gas turbines Industrial gas turbines, which are used in the oil and gas industry, for example, drive generators for power generation or compressors (mechanical drives) for gas compression or gas liquefaction. The operating temperature inside turbine acoustic enclosures can reach up to 120°C and the surface temperature of the turbine itself up to 800 °C. Oils leaking from the leaks in oil pipelines can easily TurbineProtect combines industrial fire detectors and fire detection systems and suppression control with various fire protection technologies such as:

This enables a reliable integrated fire protection solution that can be individually customised to therequirements on site. Other solutions according to customer requirements are also possible. We take the challenge Fire protection solutions for the entire hydrogen production facilities! |

|

In the V94.3A user conference there were also present multiple other important 3rd party service providers: |