Highlights of GTUsers F9FA/FB Conference 2022

The Frame 9FA/FB User Group Conference, meeting face-to-face for the first time since September 2019 in Singapore due to the COVID pandemic, is a premier customer event for End Users; vendors and OEM GE. The conference was held in Rome, Italy. Record breaking participation and lively discussions made this event successful for all participants.

Usually 9FA/FB event has been every 1.5 years but as there were so many topics to cover, it was decided to organize a new event in September 2023.

More information of the held Webinars/Conferences and coming meetings can be found at GTUsers.com

Users Session

|

The first Session was dedicated to end users only. The end user day consisted of number of case studies on noteworthy events and lessons learned. Also, Users Q&A session was added in the end of the User session where Users questions listed as part of the pre-conference questionnaire was discussed in detail.

Some of the Key lessons discussed:

- Advance Gas Path experience

- A presentations was made reviewing condition of the AGP components at first 32k inspection.

- Majority of components were in repairable and serviceable condition.

- Some turbine stages had larger deterioration (TE cracking, tip section creep) that required partial replacement of components.

- Overall reliability and availability was high during the whole 32k period.

- Plant restart after 8 years of stand still

- What has to be done after long standstill period prior restart and to modify for cyclic operation.

- Startup improvements for faster startup and ramping up with controlled loading and warming of the ST.

- Hot slow roll during stand still to increased starting reliability.

- Minimizing lean lean partial load hours by improved tuning and turn down ratio.

- 330H Generator issues

- Stator bar abrasion and rewinding of the stator.

- Project scheduling, outage duration.

- Bar enhancements.

- Site activities and validation tests performed.

- 9FB Major Inspection planned outage experience

- 35000 manhours, 488 work permits, inspection of HRSG, ST, GT, BOP.

- Covid safety requirements were extensive including thermal scanning at entrance, working teams at one location / no mixing of personnel, FFP2 masks, all logistics areas disinfected etc.

- GT exhaust diffusor cracks and long term repair solution.

- Generator rotor removal and enhancement works.

- LS2100e and EX2100e DFE Upgrades

- 9FB Compressor blade liberation failure at 70KFFH and 500FFS

- Blade liberated due high cycle fatigue crack which initiated at a corroded region of the leading edge.

- Special attention to be paid on inlet air filtration and moisture removal (access of moisture and corrosive substances), quality of water washing systems not causing erosion.

- 9FB gas turbine experience after 12 years of operation

- Detailed presentation of 9FB combustion, turbine, rotor component performance and made improvements.

- How to adjust the compressor operating limit line for maximum performance taking into account site data/conditions like inlet filtration, compressor degradation, hot section component performance etc.

- Rotor LTE

- How and when to make rotor LTE analysis.

- What has to be analyzed.

- How to prepare for rotor repair or rotor swap.

If you own and operate a F9FA/FB or H gas turbine and are not part of GTUsers Users Group, please visit now GTUsers.com and register.

|

|

General Electric

|

OEM GE Gas Power Session

GE had prepared comprehensive and technical lectures to cover questions raised by the end users. Latest technical developments and status of the fleet and latest TILs were reviewed. A special solution showcase was arranged by GE as part of the evening program.

Conference included the following main topic areas:

- 9FA/FB gas turbine in global landscape where it is estimated that wind&solar production will increase 76%, gas power 35%. Gas turbines will continue to play an role providing flexible, dispatchable, affordable and reliable power with lower CO2 emissions. 9FA/FB provides high efficiency MWe, fast ramping and low turn down.

- 9FA AGP Upgrade experience was updated and based on number of units running with AGP it is considered to be mature technology. GE showed the HGP part conditions after 32k interval explained which component details are further improved. A new AGP flex hardware is also available providing fast startup, ramp up and down features and high part load efficiency.

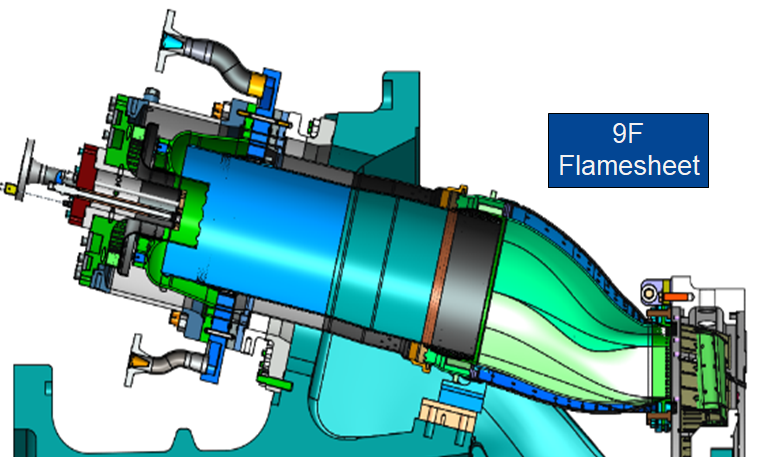

- Fuel flexibility and hydrogen capability in current DLN2.6 / DLN2.6+ and new DLN EVO combustion systems was covered as part of conference main program. An extra session in the end of conference was arranged to discuss in detail decarbonization pathway and solutions available today.

- At Outage execution and quality session GE introduced new products and improvements to solve customer issues faster, improve parts delivery time and ensure field service resources at high demand periods.

- Technical sessions covered latest TILs, S1B Gen2 experience, Rotor LTE including rotor management and Generator issues.

- Break out sessions provided in depth discussions on:

- Generator and steam turbine

- GT flange to flange

- Accessories and controls

- Outage execution

And of course most importantly; detailed replies to end user questions during the Q&A session. Again GTUsers with the SteerCo collected end user questions in advance and all questions were replied in detail by GE with lively discussion.

|

|

3rd Party Service Providers

|

MECHANICAL DYNAMICS & ANALYSIS

At 9F User Group Conference in Rome in Sept 2022: MD&A's presentation – ‘Hot Gas Path Combustion Repairs and Life Time Extensions’ covered:

- HGP Components Replacement Options

- Reliability Risks

- Life Time Extension (LTE) – Case Studies

- Fuel Nozzle Repair and new manufacture experience and capabilities

- Rewards of LTE

- Risk Mitigation

- MD&A also introduced their solution for Side Ripple Spring issues on 330H generators.

|

|

|

Arnold Group, The most advanced Turbine Insulation combined with high performance heating System.

Pierre Ansmann from Arnold Group made a presentation of their succesfull Steam turbine heating systems that reduces the startup time even 75%.

It is based on accurate 3-dimensional shaped insulation blankets for perfect fitting to turbine surface.

Benefits:

- Increased IMA (In Market Availability)

- Decreased Startup costs

- Reduced thermal fatigue and longer component MTTR (mean time to repair)

- Operational flexibility

- Increased monitoring and diagnostics for CBM (Condition based maintenance) programs

Arnold full services for gas turbines include:

- Flexible Gas Turbine Insulation Systems

- Flexible Steam Turbine Insulation Systems

- Mobile On-Site Machining Services

- Supply of temporary workers for Mechanical Field Service

- Steam turbine heating system for fast startups

|

|

PSM & Thomassen Energy

PSM & Thomassen Energy introduced latest updates on their offerings.

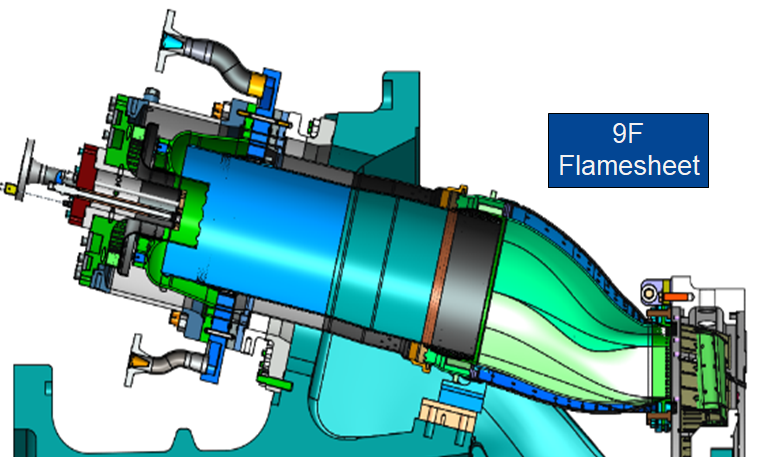

This event was a premier customer event on the PSM and Thomassen Energy marketing calendar. Existing relationships were renewed and PSM Thomassen introduced their new owner, Hanwha, and expanded portfolio of product solutions and services. As a sponsor of this event, PSM Thomassen was given a User-only presentation slot, highlighting their new references in the Japan market and retrofit FlameSheet™ combustor, giving customers a pathway toward net-zero carbon emission power production.

Most importantly, the Conference afforded an opportunity to gather “Voice of the Customer” feedback on emerging fleet issues, market trends and the reasons why customers need their assets to become more responsive to intermittent renewables coupled with improved operational flexibility. This feedback is critical when identifying and selecting necessary technologies to enable and develop new service offerings.

|

|

|

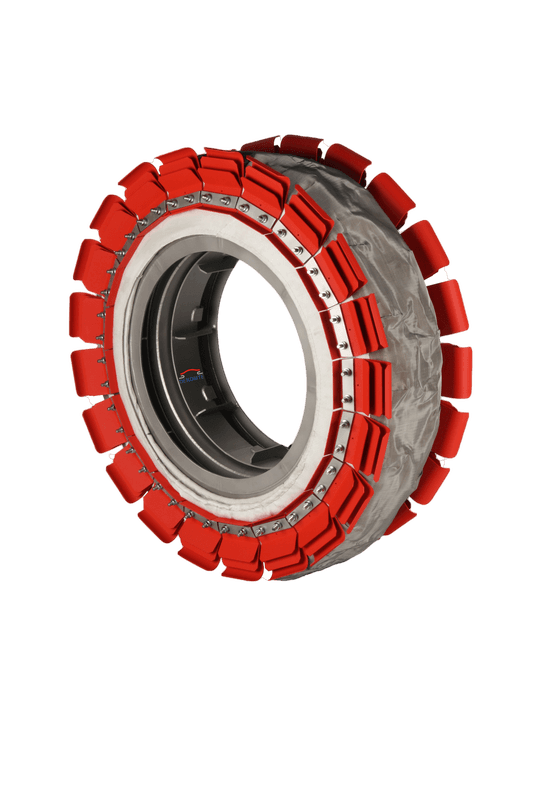

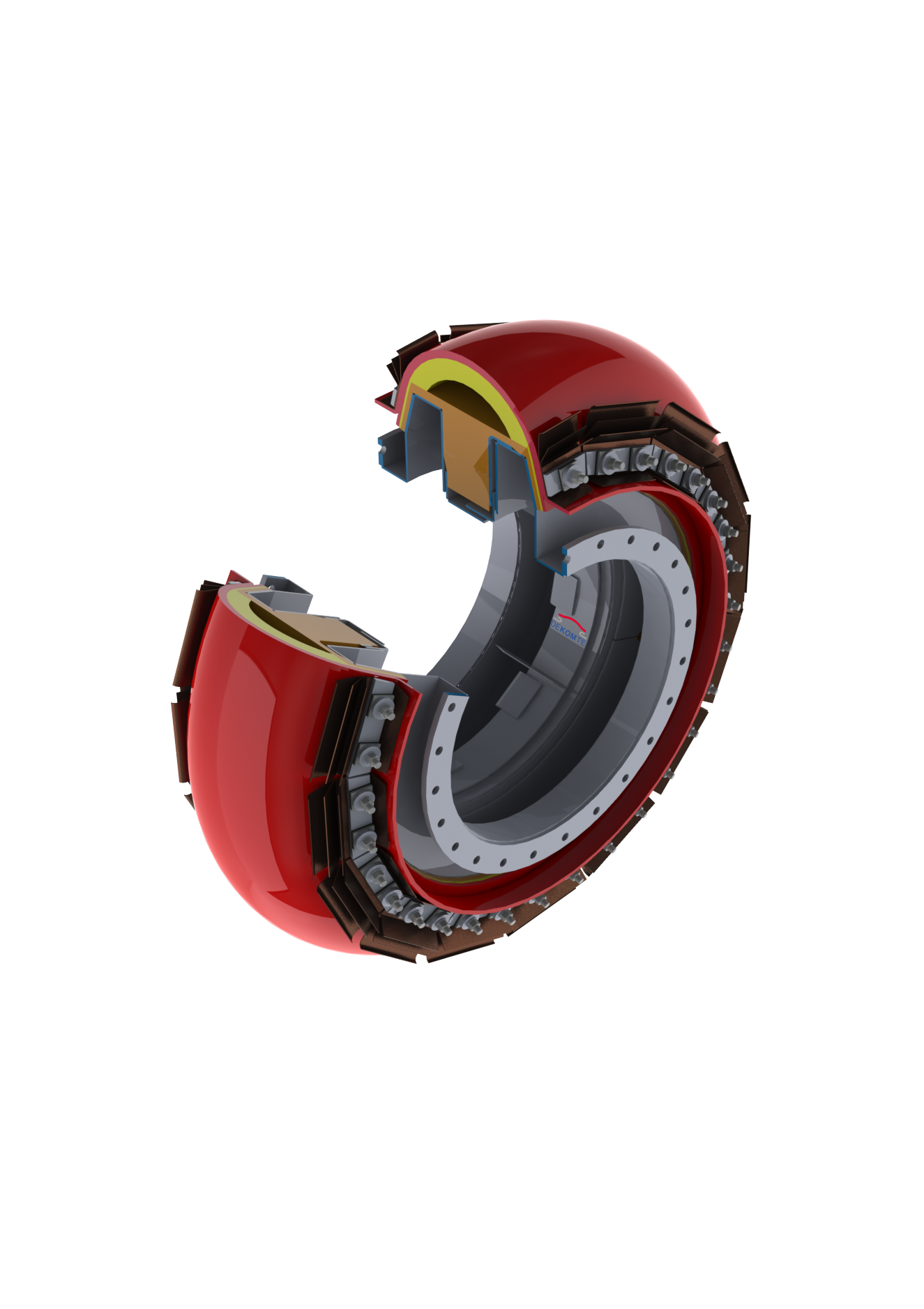

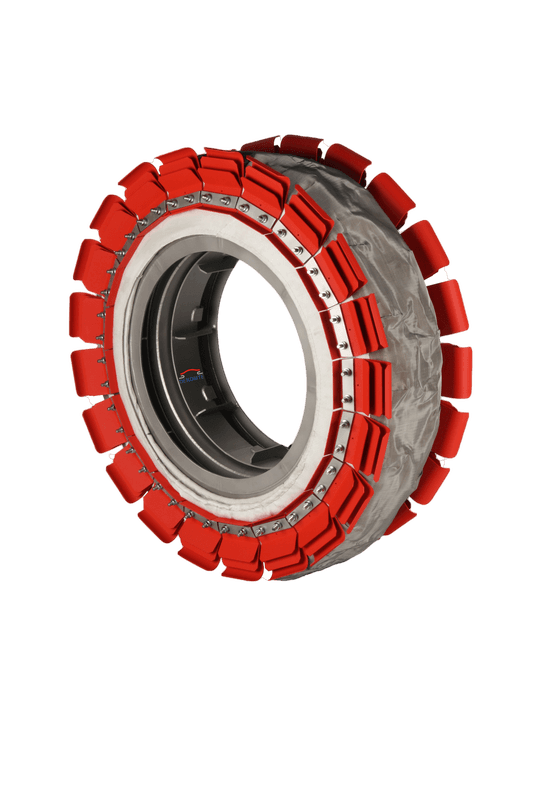

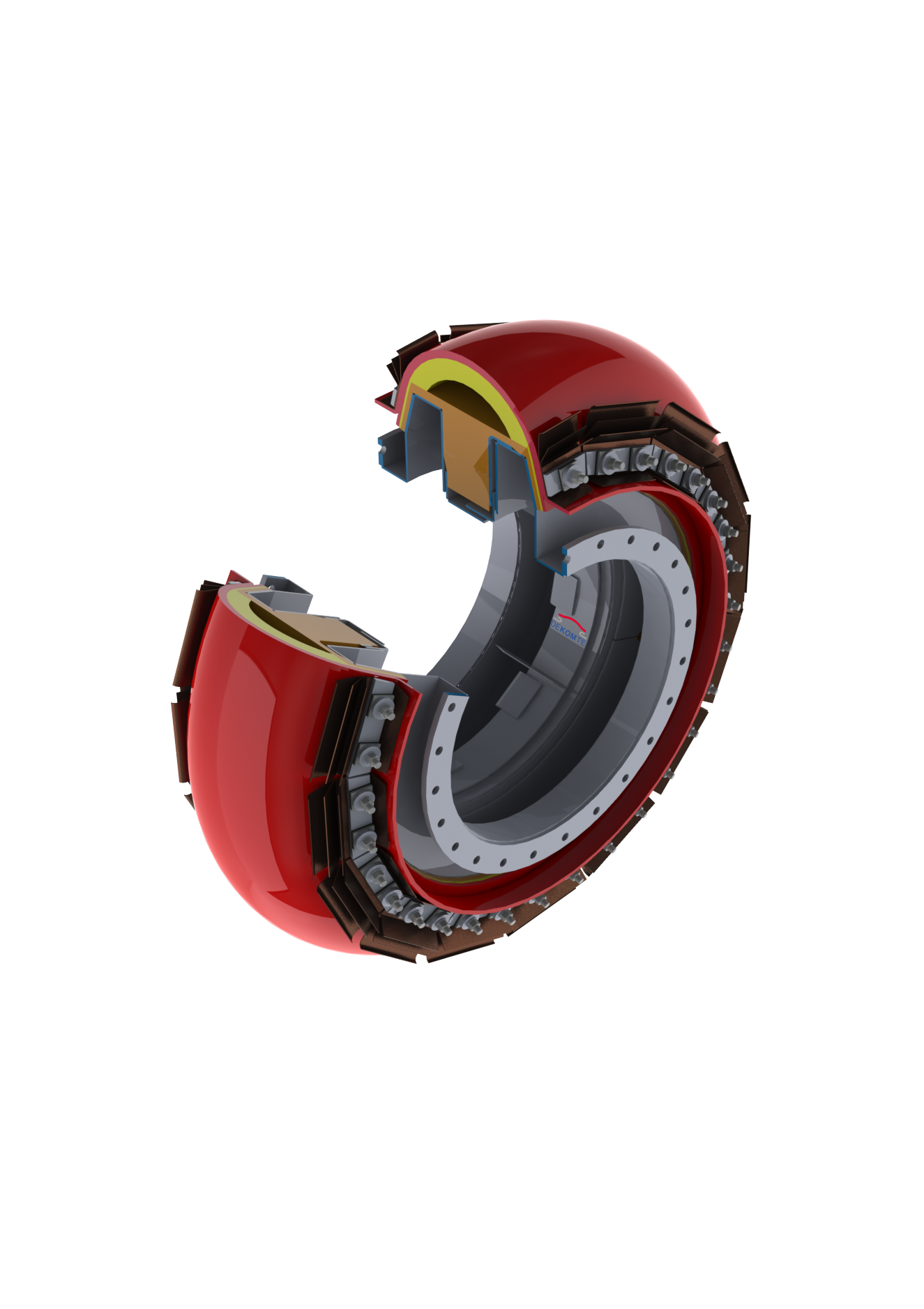

Dekomte

Dekomte manufactures fabric and metallic expansion joints and bellows, designed and constructed to compensate for changes in length due to shifting temperatures in duct work. Axial, lateral and angular movements are compensated for.

DEKOMTE expansion joints are available in any geometric shape (round, square, oval, multi-sided) and in any size.

Dekomte explained their solution provider approach to the technologies, selection and criteria for proper expansion joint selection and maintenance, in particular:

- Expansion joints for 9FA-B as OEM supplier.

- Custom designs available for 9FA-B with special DEKOMTE ‘3WA’ solutions for high cycling applications.

Dekomte also explained some of their other solutions for penetration seal retrofit applications and hot spot repair using pumpable insulation.

|

|