Highlights of GTUsers GT26 Conference 2022

A long awaited GT26 conference was held in Rome 14th-17th November. After 3 years of webinars only, the face to face live event felt like it was much needed and participants from different companies enjoyed to finally meet in person once again. Wide range of topics, lively discussions and high number of participants including 15 Sponsors made this event successful for End users, 3rd parties, Ansaldo Energia and GE Vernova.

More information of the held Webinars/Conferences and coming meetings can be found at GTUsers.com

Users Session

|

The first day was dedicated to end users. The end user day consisted of numerous case studies on noteworthy events and lessons learned. Users Q&A session was added in the end of the User Day where questions listed as part of the pre-conference questionnaire was discussed in detail between end users. Some of the Key lessons discussed:

Vendor fair was running during coffee breaks and during dedicated time prior lunch breaks. Vendors specifically having solutions for GT26 gas turbine had the opportunity to meet the end users and discuss technical solutions available. Many more topics were discussed including a lot of technical information and experience sharing between end users during the user Q&A session. If you own and operate a GT26 gas turbine and are not part of GTUsers Users Group, please visit now GTUsers.com and register.

|

|

Ansaldo Energia

|

Ansaldo Energia day

|

|

GE Vernova

|

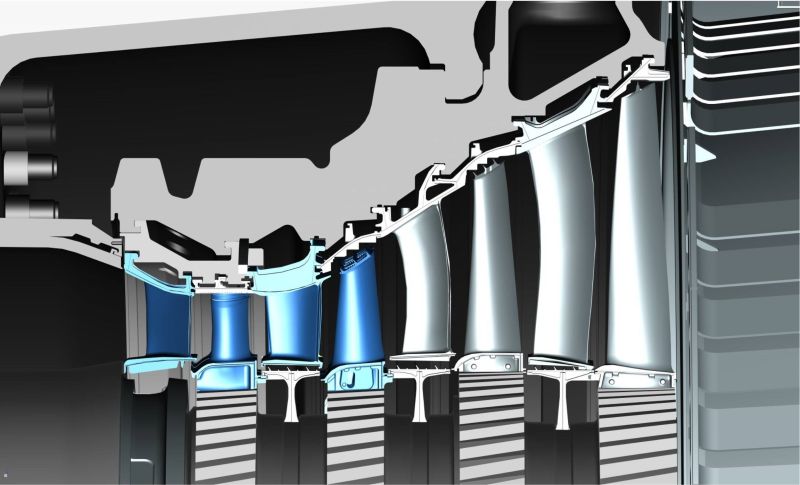

GE Vernova day GE Senior Product Manager Simone Serge highlighted GE path to reduced carbon intensity of gas plants and how to position gas power as renewables multiplier. Mandatory attributes to pursue that target are clearly the ability to support demand when it is most needed, reliability, and the possibility to expand the operational envelope beyond the originally intended profile, flexibility. GE extensively covered the latest GT and plant technical updates, relating solutions and answered end user questions raised during the conference and those collected by the steering committee in advance. GE efforts and expertise are widely recognized as they continue to work on accelerating issues resolution and on increasing successful outage execution rate. In terms of flexibility, GE talked about evolving challenges and portfolio to help convert them into opportunities - the immediate and most relevant solution being the GT26 HE upgrade. With the 8th upgrade signed during the course of the week, positive feedback was received from users who have implemented the upgrade earlier this year – an irrefutable testimony for the success and maturity of the product. In the end of conference, GE had a dedicated session on GT26 plant decarbonization with a deeper dive into pre- and post-combustion options including carbon capture technologies.

|

3rd Party Service Providers

|

FREUDENBERG FILTRATION TECHNOLOGIES Freudenberg’s brand-new spiderMaxx cassette filter celebrated its premiere at this year’s GT26 Users Conference. Thomas Schroth introduced the audience to the product’s unique features and benefits in his lecture “Maximum efficiency and operational reliability. With spiderMaxx. EPA filtration on a new level.” spiderMaxx is a new cassette filter for multi-stage gas turbine and compressor air intake systems. It boasts unique design features and offers gas turbine users greater efficiency and operational dependability with premium, EPA-level filter performance. High turbine efficiency and avoiding unplanned downtime are key factors in operating gas-fired power plants. In multi-stage filtration systems, spiderMaxx cassette filters provide optimum protection from particle ingress and moisture even at high volume flows. This prevents performance loss and malfunctions. |

|

|

|

Arnold Group, The most advanced Turbine Insulation combined with high performance heating System. Werner Arnold & Pierre Ansmann from Arnold Group made a presentation of their succesful Advanced Single Layer Turbine Warming System including detailed axial flow steam turbine case study. Benefits:

Arnold full services for gas turbines include:

|

|

Turbotect Turbotect presented how to Improve Compressor Cleaning with Biphase Detergents. Our biphase, water-based compressor cleaner TUROBTECT 2020 allows to replace solvent based detergents without jeopardizing the cleaning result. TURBOTECT 2020 is a bi-phase water-based, superior quality cleaner for on- and off-line application with an extremely high cleaning performance comparable to solvent-based cleaners. TURBOTECT 2020 is formulated as a unique blend of non-ionic surfactants and solubilizers in a water-based solution. Key features: Biphasic

|

|

|

Dekomte manufactures fabric and metallic expansion joints and bellows, designed and constructed to compensate for changes in length due to shifting temperatures in duct work. Axial, lateral and angular movements are compensated for. DEKOMTE expansion joints are available in any geometric shape (round, square, oval, multi-sided) and in any size. Dekomte explained their solution provider approach to the technologies, selection and criteria for proper expansion joint selection and maintenance, in particular:

Dekomte also explained reasons for loss of insulation and effects of insulation loss. With DeKomte methods condition of insulation can be inspected at site and corrective solutions provided accordingly. |

|

|