The first SGT800*gas turbine user conference was finally after Covid times organized in sunny Berlin.

The conference provides a unique opportunity for SGT800 Users (owners, operators, maintainers, asset managers) to meet and discuss technical topics with their peers and also to get updates on the fleet position, available upgrade options and a range of service offerings from the companies attending. This was the first SGT800* conference and we all were pleased with the positive feedback and lively discussions.

If you own and operate a SGT800 gas turbine and are not part of GTUsers Users Group, please visit now GTUsers.com and register.

Famous User Day

It is customary at the Gasre / GTUsers.com gas turbine end user meetings, that the first full day is dedicated to end users only.

The end user day consisted of case studies on noteworthy events and lessons learned. Also, Users breakout session with a Q&A was held in the end of the User day.

|

Each User made a presentation of their Plant's general configuration and main issues notified during operation and maintenance inspections with discussion after each presentation. Main technical issues were also listed in a break out session. A Quality Issues Database was established as part of GTUsers SGT800 Group web pages to follow up with all end users the topics raised. Topics will be discussed in the coming Webinars in 2022 and in the next in-person user conference in 2023. Some of the technical highlights extracted from the user day:

Operation with LNG fuels and Liquid Fuel Oil

|

|

|

Vendor fair was running during the coffee breaks and during a dedicated time reserved for it. Specific Vendors were selected for the event providing services specifically for SGT800* gas turbine. Direct contacts to suppliers and component OEMs is important to get latest news on product upgrades and support during maintenance. Real turbine parts like fuel nozzles, vanes, blades, inlet filters etc. were present at the Vendor fair. It was so different to see and touch real parts and discuss the manufacturing methods, cooling, coatings and performance of the parts. |

|

Vendor presentations

GE PowerGE session was great last week with the SGT-800* Users at Berlin. GE target was really to share our progress and show how the GE Power experience, expertise and technology are delivering on plant operation support, outage execution and the already running GE-developed parts in SGT-800* engines. GE brought their manufactured SGT800* parts to the conference, and it was especially rewarding to share details on how they are helping to increase Availability, Performance and, ultimately, reduce Cost of Electricity (while Users could see the GE Parts from up close). |

|

|

|

Arnold Group

|

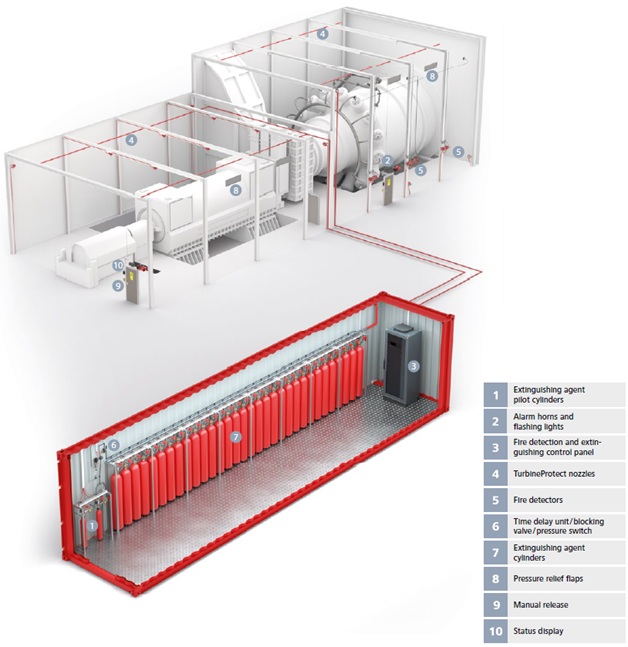

MinimaxMinimax fire detection and protection systems are installed in more than 500 Siemens Gas Turbines worldwide. Majority of these turbines are of type SGT800 and its predecessor model GTX100. Since these turbines are already in operation for years, Minimax talked about some very important aspects related to their systems. Modernization/Upgrades:

Spare Parts:

All the relevant documentation, customer information letters and presentation are available for GTUsers end users to download from the Link to Minimax page on the GTUsers website. |

|

|

|

DEKOMTEDekomte manufactures fabric and metallic expansion joints and bellows, designed and constructed to compensate for changes in length due to shifting temperatures in duct work. Axial, lateral and angular movements are compensated for. DEKOMTE expansion joints are available in any geometric shape (round, square, oval, multi-sided) and in any size. Dekomte explained technologies, selection and criterias for proper expansion joint selection and maintenance:

|

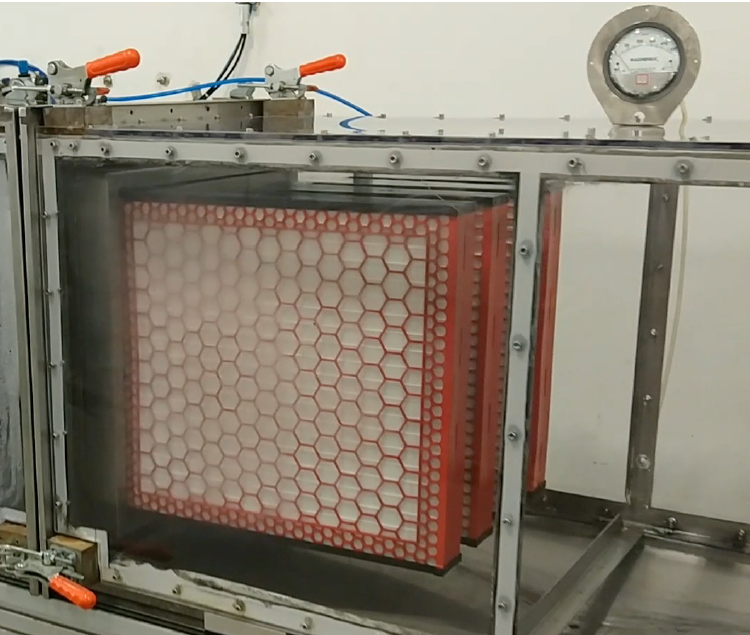

FREUDENBERGNew classification system simplifies filter selection Site- and plant-optimized solutions in intake air filtration offer operators of turbomachinery valuable potential for optimization in terms of performance, operational reliability and ease of maintenance. Up to now, the available test standards ISO 16890 (formerly also EN 779) and ISO 29463 / EN 1822 have only been of limited help when it comes to meaningful evaluation and needs-based selection of intake air filters for rotary machines such as gas turbines and compressors. The reason is that they were designed for filters used in general ventilation and airconditioning systems. This has changed when mid-September 2021 the Part 1 of the revised ISO 29461 has come into force. It specifies how the corresponding performance parameters of static air filters used in such systems are determined and classified. The 13 filter classes of the ISO 29461-1 standard create transparency, allowing filter performance to be objectively compared. The volume flow rates and final pressure drops used to determine dustholding capacity have been adapted to the realities of turbomachinery. The new standard now also describes the procedure for determining the dust-holding capacity of EPA and HEPA filters, which was previously not covered by the ISO 29463 and EN 1822 standards. In addition, ISO 29461-1 for the first time provides concrete installation specifications for testing round filter elements, i.e. filter cartridges. Classification according to T classes More information about the new standard is available at www.iso29461-1.com. As well as an explanatory video interview with Dr. Caesar, visitors can watch the online filter class configurator according to ISO 29461-1 and can download a detailed customer information with comparison tables. The industry specific e.FFECT brochure can be download here.

|

|

|

FaistFaist is committed to supply premium Air Intake Filters providing the following benefits for SGT800 operators:

Faist is Siemens’ approved OEM. |

*) SGT800 is a Trade Mark of Siemens Energy.